Manual washing stations can be of various types: cold or hot, with soaking, low pressure or high pressure. Which manual parts washer is best suited to your needs? Let's try to understand it.

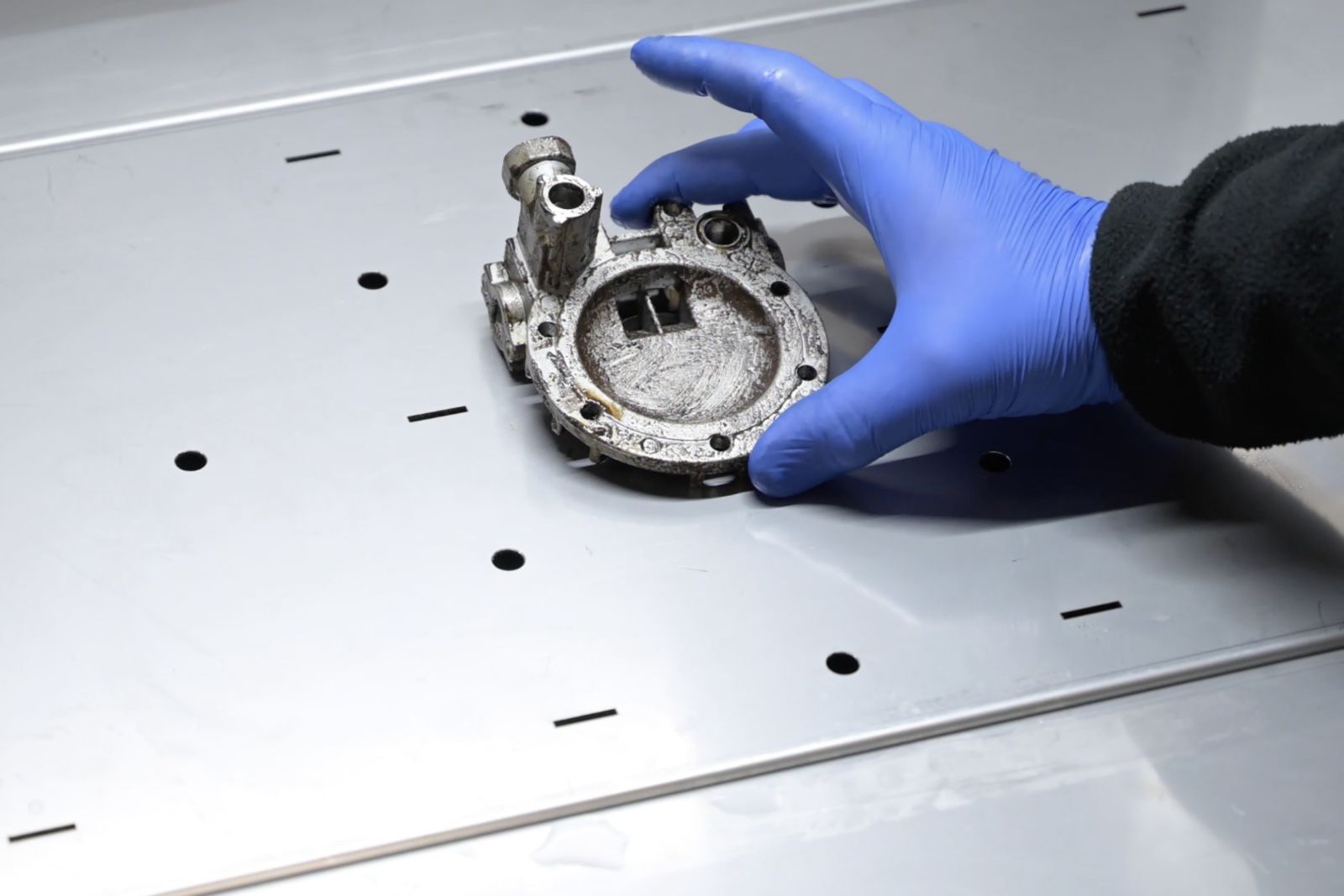

Let's start with why to choose a manual parts washer: when it comes to industrial production environments, automation in washing may not always be the most appropriate answer. Very often cleaning assisted by the human eye is necessary, therefore with the presence of an operator who acts in a specific area of the piece to be washed with a spatula, brush or nozzle.

Washing stations

When it comes to industrial manual washing it is necessary to talk about washing stations rather than simple "washing tanks", precisely because in some situations an extremely precise and stringent quality is absolutely necessary. Manual washing stations can be of various types: cold, hot, soaking, low pressure or high pressure or even a mix of the various types.

When we talk about a manual station, we cannot help but think of the basic model which has a dispensing brush which makes cleaning more precise, allowing the operator to reach even the internal corners of the pieces to be washed, which would otherwise be hidden and unreachable.

Our solution in this category, economical but very functional, is the solvent-based manual washing station with dispenser brush Top Cleaner 900 Pneumatica , which allows you to act in very short times on specific areas of the pieces to be washed.

Manual washing with an integrated tank

To remain competitive in your sector, the production process requires increasingly faster working times and an increasingly higher quality standard. Cleaning, in this area, is fundamental, and the operator must be able to clean as many pieces as possible without interrupting the production flow.

In cases like this, it is necessary to have a washing station that not only allows you to clean the pieces in a targeted way, but also gives the possibility of softening the dirt to remove it more quickly. Considering that the use of water-based detergents is the most popular, the different washing and use methods must also be taken into account.

For these particular needs, at Geicos we have implemented a washing system with an integrated heated tank. Thanks to the hot water and the chemical action of the solvent, the dirt is softened before being cleaned with the dispenser brush. This allows the operator to carry out his work quickly and efficiently without having to stop or slow down production.

Our proposal in this category is the Top Cleaner 90 Bio Power in Aisi 304 stainless steel and a tank system heated to a maximum temperature of 45°.

High pressure manual washing

In cases of stubborn dirt, where there is a need to eliminate greases, oils or resins from processing for which simple soaking is not enough, high pressure comes into play. Sometimes it happens that, with this type of substance, the chemical action of the detergent and soaking in water may not be enough, so a more targeted and precise action is needed which forcibly removes everything that cannot be removed. remove by rubbing and soaking.

To respond to this need, we implemented the washing station with a diaphragm pump system that shoots the detergent heated to 40 bar with a flow rate of 20 l/m. The ECO HP 110 allows the operator to act expertly in the necessary washing area thanks to the dispensing nozzle.

A further evolution of this high pressure manual parts washer are the washing stations such as the Top HP 110, which allows also:

- Low pressure cleaning by dispensing brush;

- Soaking;

- High pressure cleaning by nozzle.

Technologies behind manual parts washers

The Geicos range has expanded over the years following market needs and anticipating or pushing the evolution of manual washing stations. All Geicos brand creations are developed in compliance with European regulations regarding safety and quality.

The concept behind the washing stations is always the circulation, filtering and reuse of the washing detergent, whether water- or solvent-based. The use of AISI 304 stainless steel allows the washing station to be solid and guarantees long durability over time, something that plastics or ferrous materials cannot provide.