Knowing how to find better ways to simplify and reduce manufacturing times and processes is the basis of innovation. In this case study we will see how, based on specific customer requests, we have modified our automatic D100 to speed up and optimize bodywork washing and drying times.

The Client

With a history of over 25 years, the company has established itself as a point of reference for professionals in the industrial and automotive sectors across Europe. Specializing in professional maintenance with the advice of experts and cutting-edge technologies, for years it has been setting new quality standards in the development of products tailored to the needs of its customersi.

The company decided to turn to us to obtain a tailor-made product, based on specific washing needs, in order to make the production process more efficient.

The Target

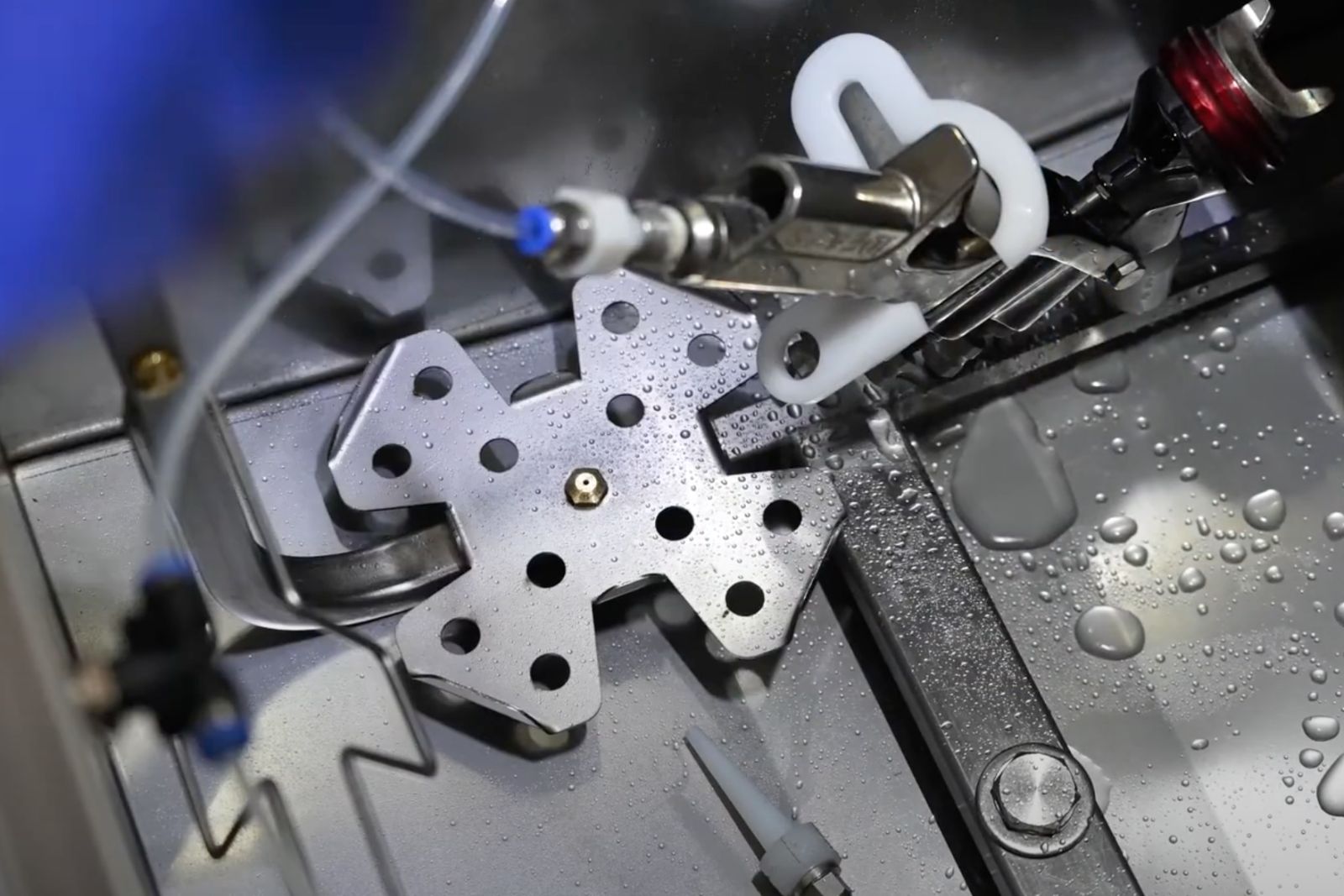

The creation of a water-based washing machine for spray guns used for body shops. For this specific machine, flocculation was not necessary and instead the equipment was reorganized automatically.

The main target was to be able to reduce the washing and evaporation times of the applied product, creating a new activation circuit of the venturi system, i.e. vapor extraction, connected directly to the washing timer.

In short:

- Reduce washing and drying times;

- Perfect the cleaning of PPS connection gun washers.

Solution

To create a water-based cleaning product for spray guns, we selected a standard machine, the D100 Automatic, from which to begin the design and restyling.

Having analyzed the customer's requests, our engineering team immediately took action to identify the critical issues and the necessary changes to be made to the circuitry of the D100 Automatic spray gun washer to optimize washing and drying times. Once the first prototype was created, we provided the equipment to the customer, so as to be able to carry out road tests, with their customers, to see if the prototype was adequate or needed further modifications.

When you intend to introduce new washing products, the necessary times for the testing phase must be calculated, as they are essential to be able to analyze all the various scenarios and the various critical issues that may emerge over time. Furthermore, a key point of our work was the standardization of the equipment, as it is necessary to find the right balance between usability, feasibility and simplification of the systems. In fact, the market of those who use our equipment is very broad and with many differences in terms of needs.

Following the design and commissioning of the equipment, we proceeded to create a survey, useful for collecting all the data necessary to better understand the results of the tests carried out and understand if further maintenance work was necessary.

Results

From the results of the analysis of the data collected through the survey, we conclude that the design objective was successfully achieved. Thanks to the new tailor-made product, the customer is now able to speed up and improve the bodywork processing system of that specific process, thus managing to increase his daily productivity.

Furthermore, thanks to this improvement, the company is now able to eliminate further steps in the manufacturing process, thus managing to reduce the qualitative difference in its work.

The customer, given the results obtained from the work, is considered largely satisfied. After an initial period of testing the equipment and ascertaining the improvements that it is capable of bringing, he decided to include the entire series of Geicos gun washer products in his equipment .

Given the excellent result obtained from the tests of this product, we have decided to make the equipment available also for other customers, inserting new options for greater customization.

Do you also want to speed up and optimize your work? Take a look at our e-commerce.