As we well know, parts washers are not all the same: they have different characteristics and respond to specific cleaning objectives, which differ from each other. The main distinction is that between manual parts washer and automatic parts washer.

There are also cases in which the machine has characteristics in common between the two types of parts washers and can be a hybrid between manual and automatic. As happens, for example, in the case of our new HP Compact, of which we will see the characteristics in the course of the article.

At a certain point in the decision-making phase that will lead you to choose the right parts washer for your needs, you will find yourself wondering whether to choose a manual tool or an automatic alternative. In this article we will see what are the main advantages of the first type of machinery.

The level of accuracy guaranteed by manual cleaning

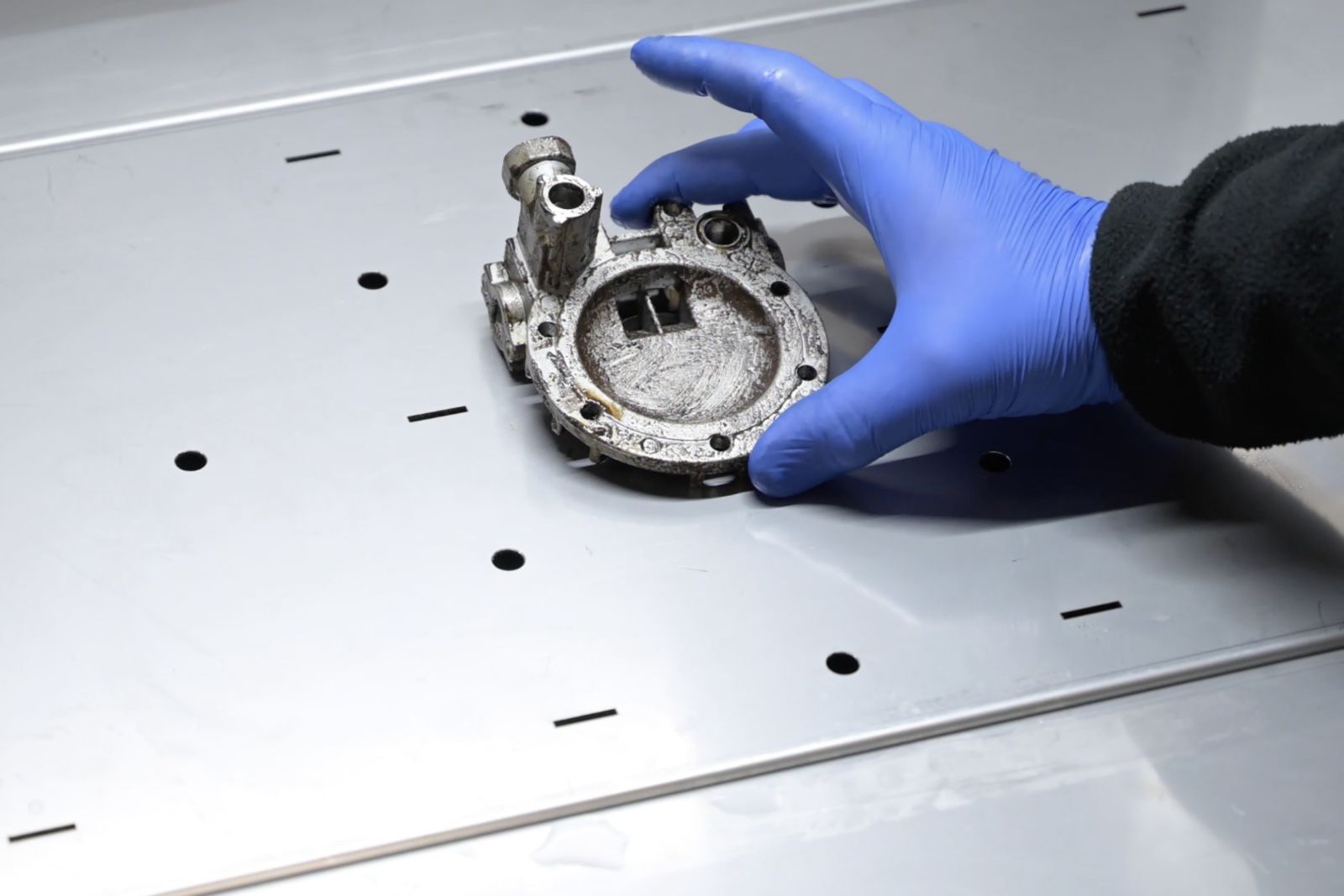

The manual parts washer allows you to concentrate the washing of the industrial piece in specific points that need more cleaning than others. In fact, the operator can orientate the washing efficiently, even cleaning internal areas that are not very accessible.

Its work is facilitated by a dispensing brush which makes even more precise cleaning of internal cavities otherwise difficult to reach. In this way, attention to the details of human work is combined with the washing efficiency guaranteed by the machine.

The manual parts washers are ideal for the thorough and precise cleaning not only of small and medium-sized pieces, but also of components with larger shapes (an example is our Top Cleaner 140 Bio Power). The solutions are numerous, so it is good to study the characteristics of the machines on the market in depth, always keeping in mind your personal washing needs.

The different types of manual parts washers

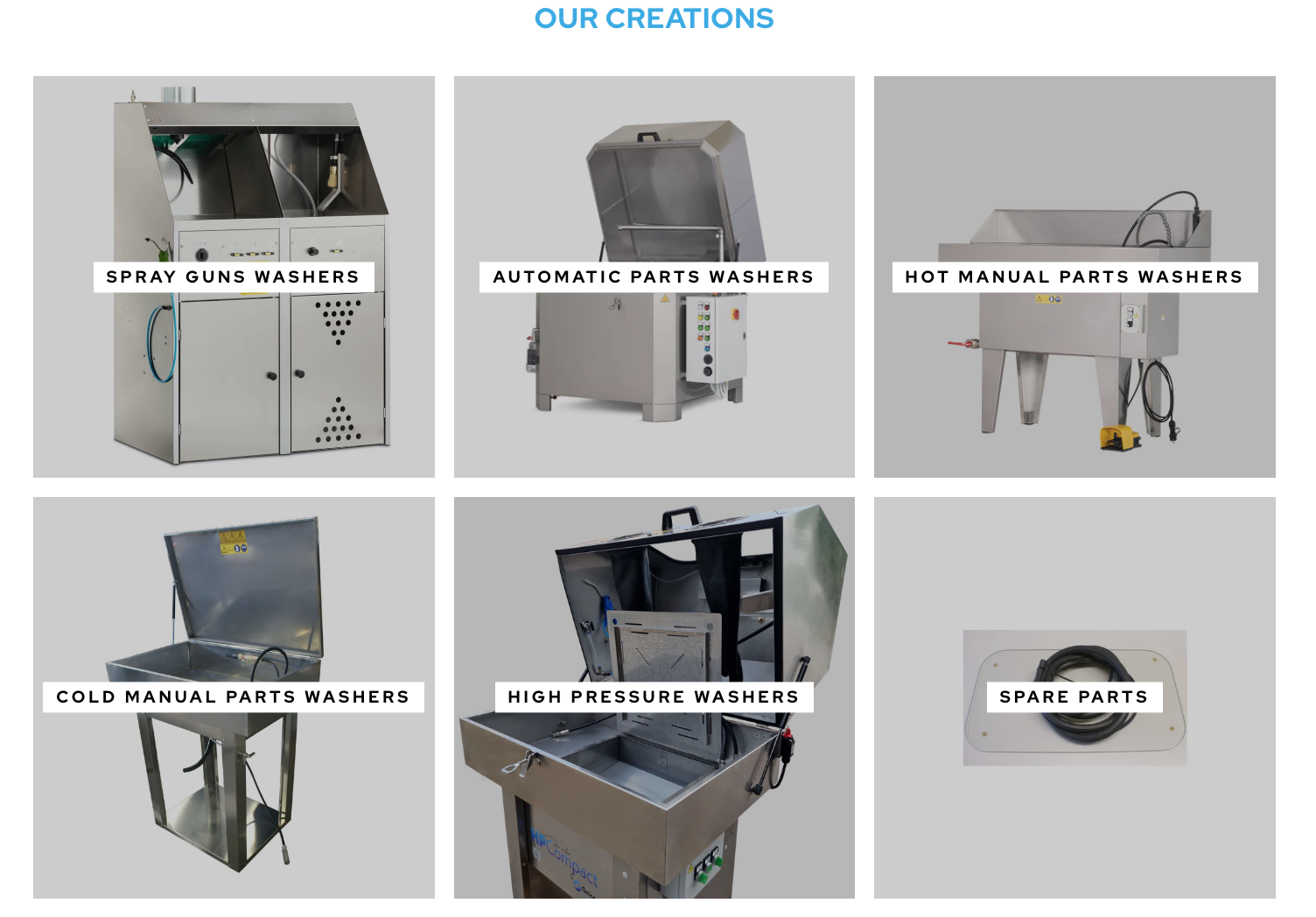

Precisely because the cleaning needs can be disparate, in the same way the available solutions are different and specific. Just as the parts washers in general are divided into automatic and manual, in turn the manual parts washers are divided into 3 sub-categories:

- hot manual parts washers, which reach a maximum temperature of 45 ° and use a detergent based on heated water;

- cold manual parts washers, which allow washing through the use of a solvent;

- high pressure manual parts washers, which we have already talked about when we saw the importance of flow rate and pressure in this type of machinery.

The principle behind it is always the same: to ensure thorough and effective cleaning of medium-small components with direct control by the operator at all stages of the washing. Depending on the particularities of the parts that you will have to wash, you can orient yourself on one (or more) of these categories.

Our new proposal: HP Compact

HP Compact is a manual hot part washing machine, which represents the evolution of the classic manual washing equipment with the addition of 2 extras:

- The possibility of soaking the piece: the operator can leave the piece to soak and, while the temperature and the chemical action of the detergent take effect, take care of the other functions. Once the piece has been returned to the support grid, you can complete the cleaning of the piece with the dispensing brush;

- The implementation of a closed booth with LED light, anti-fog system, glass and gloves and a hose with nozzle that works at 5 bars.

Thanks to its characteristics, this machine can be considered to all intents and purposes a hybrid between a manual parts washer and a high pressure one. It is ideal for washing small and medium-sized parts.

Are you looking for manual parts washers for cleaning your components?