In this article we will explore the fundamental differences between water-based cleaners and chemical solvents. We will focus not only on their characteristics, but also on the differences in regulation, use and environmental sustainability.

This overview aims to respond to all those companies trying to understand which detergent may be most suitable for own needs. There are many differences and each type of detergent has its own positive and critical sides: let's find out.

Sovent Vs water-based cleaner

In the dynamic world of industrial production, choosing a detergent is never trivial. It is a complex equation where the desired result is an immutable constant: a level of cleanliness that leaves no room for streaks, processing residues, grease or oils. This objective is not only fundamental to guarantee the quality and reliability of finished products, but is also a reflection of the image and philosophy of a company.

The difference between chemical solvents and water-based cleaners isn't limited to their ingredients; it also affects the environment, workplace safety and the level of cleanliness they can guarantee in different work environments. This choice becomes a bridge between production efficiency and commitment to eco-compatible and responsible practices. The decision on which path to take depends on an accurate analysis of the production process, considering that each work environment has its own specificities, from the types of machinery used to the particular cleaning and maintenance needs.

From this perspective, the selection of the detergent represents a strategic choice that has a profound impact on efficiency, sustainability and processing times. Each solution has its own distinctive benefits, shaped to fit unique needs and well-defined business philosophies. The heart of the matter lies in balancing these factors, always aiming for the operational excellence that every company wishes to achieve.

Solvent cleaners

Solvents are liquid products effective in dissolving various types of substances, from solid to liquid and gaseous ones. Their ability to deliver high-quality cleaning results in a short time has made them a popular choice in many industrial sectors. Part of their popularity comes from the ability to achieve such results without the need for additional manual interventions, such as the use of brushes or the action of washing nozzles, simplifying the cleaning process.

Nonetheless, solvents present specific considerations related to their environmental impact and workplace safety regulations. The management of waste requires attention, especially regarding more specific disposal processes, due to their chemical characteristics. The use of these products also implies the adoption of personal protective equipment (PPE), such as masks, gloves and glasses, and fume extraction systems, to ensure the safety of workers.

The decision to use solvents is therefore based on an overall assessment that includes the need for effective and rapid cleaning, the available budget and safety and environmental sustainability practices. For companies that need an effective, fast cleaning process and are equipped to guarantee both worker and environmental safety, solvents can represent an adequate solution.

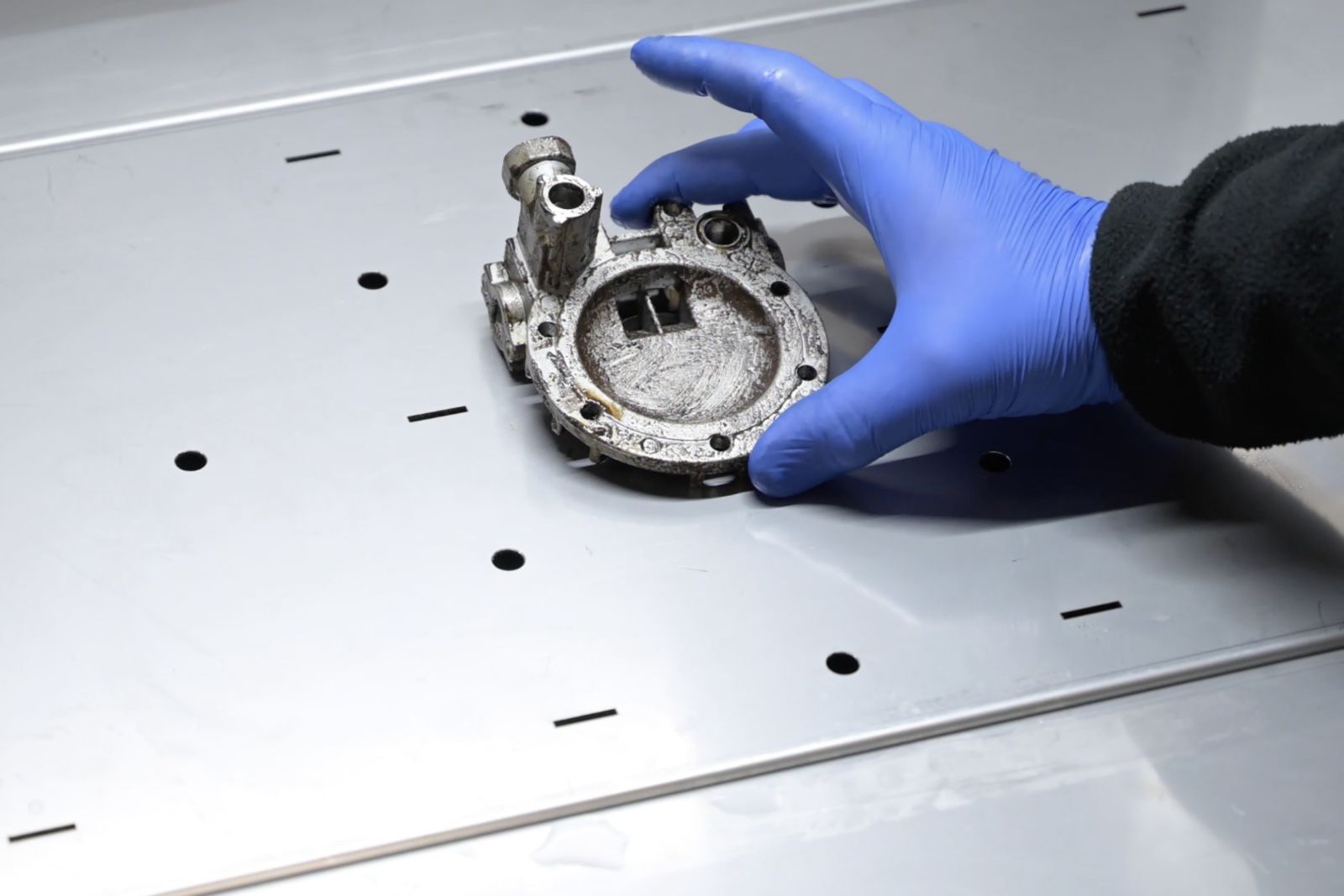

At Geicos we create various machines designed for the use of chemical solvent-based detergents. An example is the Top Tinwash: a parts washer tank in Aisi 304 stainless steel, designed for automatic washing with a basket for small and medium-sized parts, with solvent. This machine also already has the predisposition for fume extraction, furthermore in its standard setup we find the piece support grid, the washing spider in the tank and the double diaphragm pneumatic pump. This type of machine is mostly used in the automotive and graphics industries.

Water-based cleaner

Water-based cleaners are an excellent choice for companies aiming to combine cleaning effectiveness with a safer and more sustainable approach. Thanks to their non-flammable composition, the absence of volatile organic solvents and phosphates, as well as their high biodegradability, these detergents minimize environmental impact and significantly reduce health risks. Their formulation has been designed to be delicate on sensitive materials such as plastic, gaskets, rubber and metal surfaces, while offering an effective cleaning action. Compatibility with high pressure and high temperature cleaning systems further amplifies their versatility and effectiveness, making them suitable for a wide range of industrial applications.

Manipulating pH in water-based solutions is a powerful lever for addressing different types of soiling and contamination. By adjusting the acidity or alkalinity of the solution, it is possible to optimize the removal of specific substances: acidic solutions are particularly effective against limestone deposits, rust and metal oxidation, while alkaline ones are ideal for eliminating salt residues, organic dirt, metal shavings and grease.

The adoption of water-based detergents also translates into significant economic savings linked to residue management. The evolution of technologies has made increasingly eco-compatible solutions available on the market, which allow us to reduce the polluting load and the costs associated with waste disposal. Although the use of these cleaners may require slightly longer cleaning times than traditional solvents, the overall balance of cost, environmental benefits and safety makes them an advantageous choice for companies. However, it is important to consider that production times may be slightly longer, so as not to compromise overall operational efficiency.

In the vast range of products that Geicos offers, we can take the example of the Washer 1150 E Power automatic parts washer tank in Aisi 304 stainless steel. Designed for automatic high-pressure washing, with rotary basket with water-based detergent heated to the maximum temperature of 60°. The heated detergent tank is integrated and has a capacity of 210 litres.

The standard setup includes, in addition to the stainless steel basket, also the washing ramps and the double impeller pump, both in Aisi 304 stainless steel. The machine is also equipped with a safety micro, controlled opening with gas springs or cylinders tires and hermetic seal.

This parts washer is perfectly suited to a variety of industrial sectors, highlighting its flexibility and efficiency. In the automotive sector, it facilitates the cleaning of mechanical components, effectively removing oils and greases. It is also useful for extracting chips in workshops, keeping machine tools clean and ensuring their correct functionality. In the world of cosmetics, it ensures the sterilization and cleaning of the systems, a crucial phase to guarantee the quality of the products. In the molding industry, it helps keep molds free of residue, improving production quality. Infine, in the railway sector and for maintenance activities, offers effective solutions for cleaning and maintenance of components, supporting the reliability and safety of operations.

How to choose the correct cleaner?

After examining the characteristics of the individual detergents we can get to the crucial question: how do I choose the detergent that is right for me?

There are many factors that can influence the choice of one detergent over another, we have addressed them point by point on our in-depth page on products for industrial washing: solvent vs water.

One of the fundamental aspects that you need to pay attention to when choosing a detergent is its compatibility with the various materials it will come into contact with during the cleaning process. The use of an inappropriate detergent could damage the components, compromising their physical and aesthetic integrity but also their functionality.

This is why at Geicos we have a well-defined working method with which we guarantee the best result for each type of material. For us, it is essential to listen to the customer to understand all his needs and ensure the maximum reliability of our products.

Industries work with a wide variety of materials, from stainless steel to titanium in metal applications, from plastics to composites in more modern applications, to rubber and silicone for seals and flexible components. Each material has specific chemical and physical properties that you need to know in depth when using a detergent.

In conclusion, choosing the right detergent varies based on each specific business need. Both products can be valid solutions, just as both have their own strengths and weaknesses. It will be the company's choice to decide which solution to adopt based on the logistical and organizational aspects.

Every business has unique and essential needs that are reflected in specific objectives. The careful selection of the right detergent is the starting point to achieve these objectives effectively and optimally. Detergents play an essential role in the industrial cleaning process, being crucial for achieving satisfactory results.