As happens in every sector, parts washing machines are also constantly evolving to best meet changing needs. Thanks to the continuous dialogue with our customers we have enhanced the performance of high pressure parts washers.

Restyling of High Pressure Washers

As happened with the Washer 1150 E Power automatic industrial parts washer, which gave life to the new Washer 1150 X capable of handling a load of 800 kg, we have collected the needs of our customers also for the Top High Pressure and Top 110 HP machines . We have carried out a real restyling of both models, keeping the functions intact and improving some performances, through:

- The simplification of maintenance;

- The increase in security;

- The improvement of some qualitative aspects.

Worker safety has been our absolute priority. The closure of the cab has been further strengthened by making changes to the linkages and using more powerful gas springs.

This update has ensured greater stability, smoothness and resistance in closing the car door.

We then replaced the steel drip catcher at the bottom of the door with a nylon one. In addition to preventing glove liquid from escaping from the booth, it significantly reduces the risk of glove crushing when closing the booth.

Our customers choose us for the quality and reliability of our equipment. We therefore decided to replace the submersible pump used to feed the brush with a new electric pump external to the water and detergent mixture tank. The modification further extends the life of this component, thus reducing the need for replacement.

Greater practicality and ease of maintenance

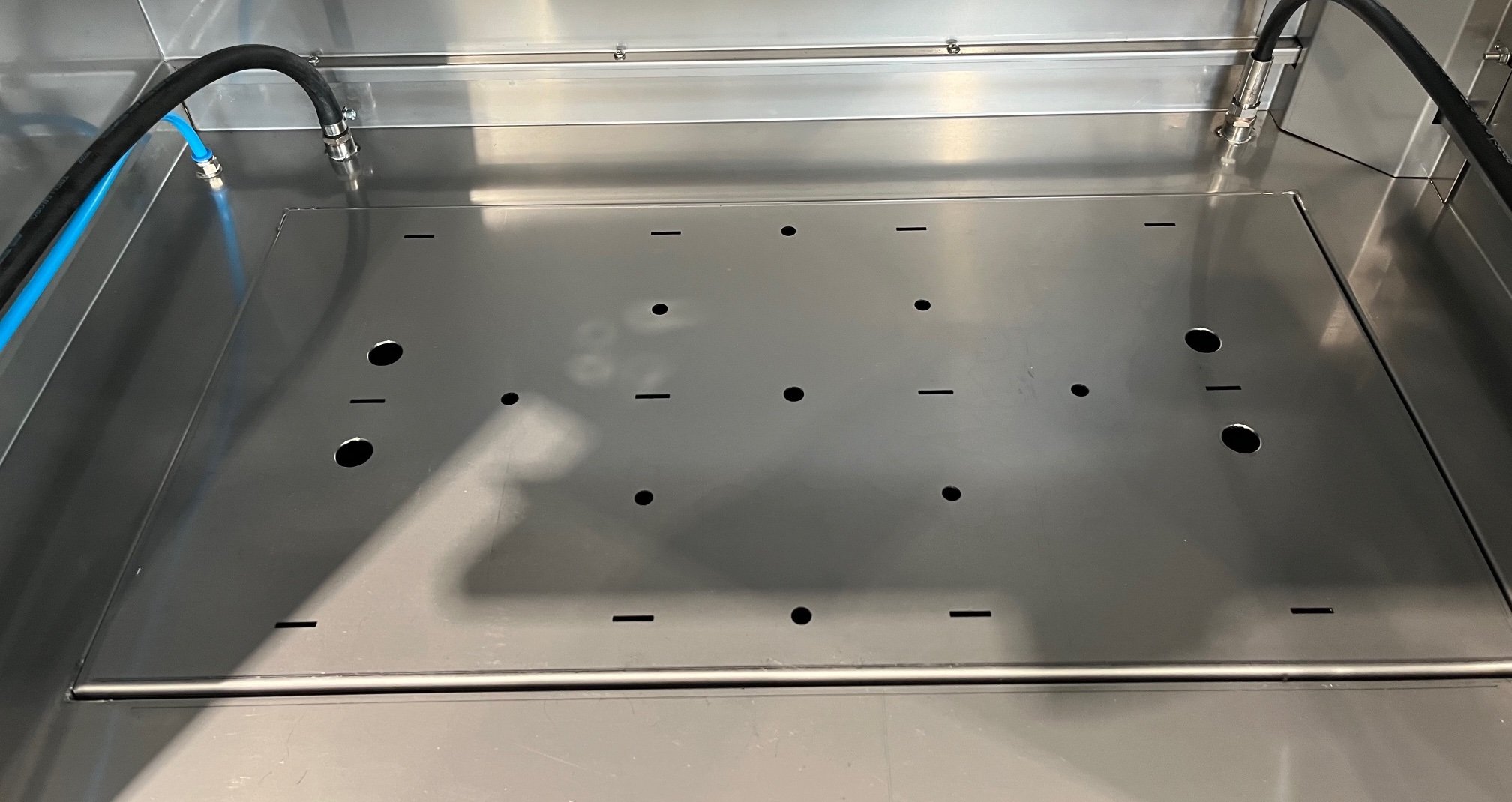

Another primary goal was to reduce the time required for daily maintenance. We have introduced handles on the support grid for the pieces and applied two holes at both ends of the grid, to make it easier to move.

Finally, we have revolutionized the filtering system, introducing an extremely efficient and easy to remove basket filter.

These improvements not only improve the performance of the Top HP and Top 110 HP high-pressure parts washers: they have also been designed to minimize the ancillary costs for replacing parts. In the case of the filtering system, we have opted for a replacement made entirely of steel, which will remain durable and resistant over time, without the need to replace it.

The satisfaction of our customers is an absolute priority, therefore many of our restylings start from the discussion on what to improve together.

Do you want to know more about our creations? Contact us for professional advice.

.png)